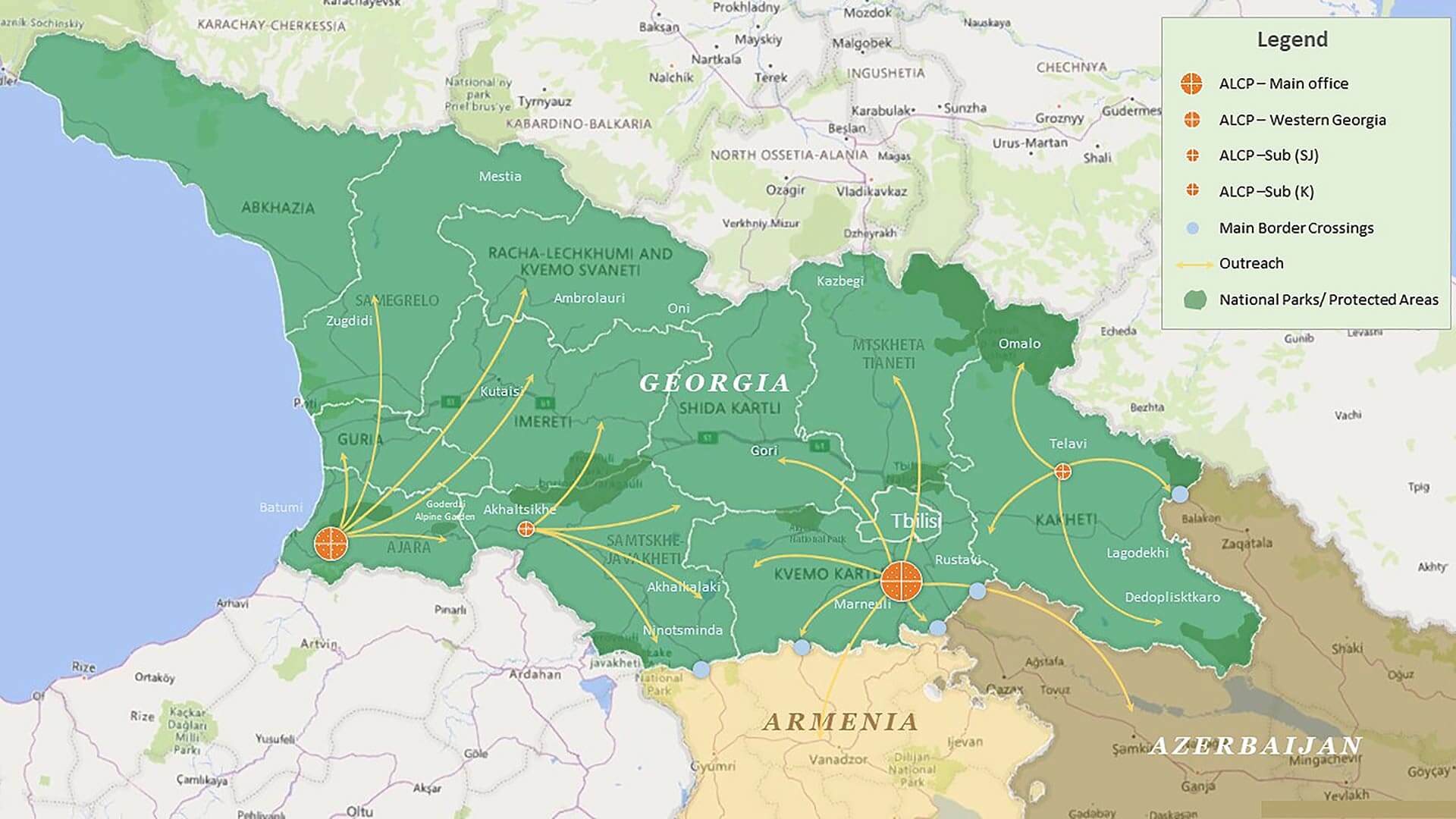

Alliances Caucasus 2 is a market systems development programme targeting rural producers in Georgia. Its purpose is to increase incomes and improve livelihoods through better, sustainable productivity, resilient market access, local employment opportunities and more equitable inclusion in local natural resource use.

The programme is the Swiss Development Cooperation (SDC) project in cooperation with the Austrian Development Cooperation (ADC) and the Swedish International Development Cooperation SIDA, implemented by Mercy Corps Georgia.